3.6V C ER26500 Li-SoCl2 Battery (8500/9000mAh)

- * High and Stable Voltage

- * Energy Density up to 590Wh/kg

- * Long Shelf Life (less than 1% per year after 1 year of storage at +25℃)

- * Wide Operating Temperature (-60℃~+85℃)

Specification of ER 26500

| Open circuit voltage (at 25°C) | ≥3.65V |

|---|---|

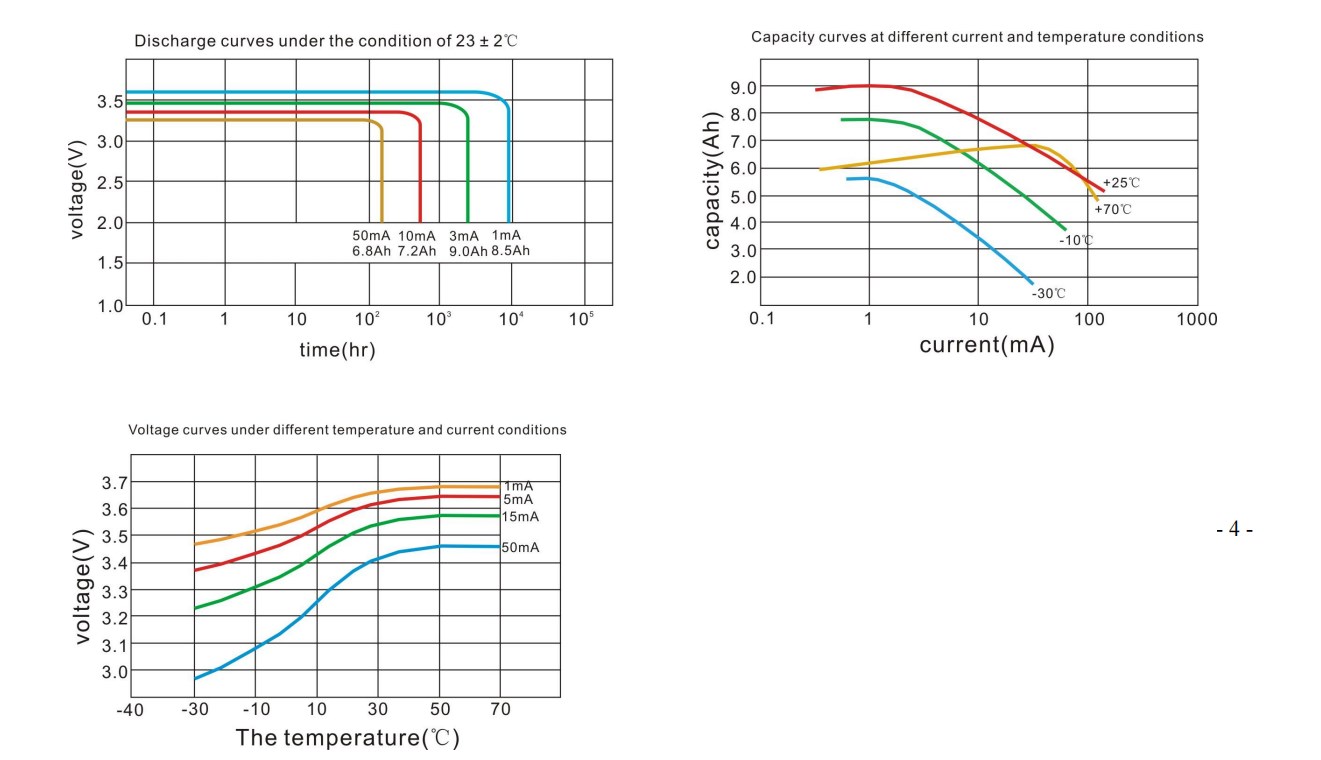

| Nominal capacity | 8500mAh |

| (At +25°C, the battery is discharged at continuous current 3mA until the voltage reaches cut-off voltage 2.0V. The capacity can vary at a different temperature, discharge current or cut-off voltage.) | |

| Maximum continuous current | 150mA |

| (New cell, at +25°C, 2.0V cut-off, battery discharged for minimum 50%°C of nominal capacity.) |

|

| Maximum pulse discharge current | 250mA |

| (300 mA/0.1 second pulses, drained every 2 minutes at +25°C from undischarged the new cell with 10 uA base current, yield voltage reading above 3.0V. The readings may vary according to the pulse characteristics, the temperature, and the’s previous history. Fitting the cell with a capacitor may be recommended in severe conditions, consult PKCELL.) | |

| Storage (recommended) | ≤30°C, ≤75%RH |

| Operating temperature range | -55°C to +85°C |

| Diameter | 25.6±0.2mm |

| Height | 49.1±0.5mm |

| Typical weight | 55.0g |

| Li metal content | 2.4g |

| Available Terminations | 1) Standard terminations 2) Solder tabs 3) Axial Pins 4) or special requirement (wire, connectors, etc) |

Alarms and security systems, GPS, metering systems, memory back up, tracking system and GSM communication, Aerospace, Defence, Military, Power Management, Portable Devices, Consumer Electronics, Real-time clock, Tracking system, Utility metering,etc.

Single battery with Cables and Connectors is Available. If the voltage or capacity of a single battery does not meet your requirements, we can supply battery pack solutions!

Warning:

1)These are non rechargeable batteries.

2)Fire, explosion and burn hazard.

3)Do not recharge, short circuit,crush, disassemble, heat above 100℃ incinerate.

4)Do not use the battery beyond the permitted temperate range.

On the other hand, spirally wound construction involves rolling the electrodes, separator, and electrolyte into a tightly wound spiral configuration. The positive and negative electrodes are wound together with a separator in between, forming a spiral-shaped core. This core is then inserted into a cylindrical metal casing, providing structural support and serving as the outer shell of the battery. The larger surface area of the anode and cathode allows for high-rate discharges.

Bobbin construction cells have a distinct feature where the anode and cathode have a relatively small shared surface area. In this type of cell, a single cylinder of cathode material is surrounded by the anode material. Due to the low common surface area, these cells have limited capability for high-rate discharges but an increased space to hold more anode material, allowing for more energy to be stored.

Passivation is a surface reaction that occurs spontaneously on the lithium metal surface in all primary Lithium batteries with liquid cathode material such as Li-SO2, Li-SOCl2 and Li-SO2Cl2. A film of lithium chloride (LiCl) quickly forms on the lithium metal anode surface, and this solid protecting film is called the passivation layer, that prevents direct contact between the anode (Li) and the cathode (SO2, SOCl2 and SO2Cl2). Put simply, it prevents the battery to be in permanent internal short circuit and discharging of its own accord. That’s why it enables liquid cathode-based cells to have a long shelf life.

This passivation layer acts as a barrier, reducing the loss of stored charge and minimizing self-discharge over time. As a result, Li-SoCl2 batteries can retain their charge for long periods, making them ideal for applications requiring low self-discharge rates, such as in remote sensors, backup power systems, and other devices that experience intermittent use.

The longer the time and the higher the temperature, the more serious the passivation of lithium thionyl chloride batteries.

The passivation phenomenon is an inherent characteristic of lithium thionyl chloride batteries. Without passivation, lithium thionyl chloride batteries cannot be stored and lose their use value. Since the lithium chloride generated on the surface of metallic lithium in thionyl chloride is very dense, it prevents further reaction between lithium and thionyl chloride, making the self-discharge reaction inside the battery very small, which is reflected in the characteristics of the battery, that is, the storage life is more than 10 years. This is the good side of the passivation phenomenon. Therefore, the passivation phenomenon is to protect the battery capacity and will not cause the loss of battery capacity.

The adverse effects of the passivation phenomenon on electrical appliances are: After a period of storage, when it is first used, the initial operating voltage of the battery is low, and it takes a certain amount of time to reach the required value, and then to the normal value. This is what people often call "voltage lag". Voltage lag has little effect on uses that do not have strict time requirements, such as lighting; but for uses that have strict time requirements, if used improperly, it can be said to be a fatal flaw, such as weapon systems; it has little effect on uses where the current does not change much during use, such as memory support circuits; but for use conditions where the current occasionally changes, if used improperly, it can also be said to be a fatal flaw, such as the current smart gas meters and water meters.

1. Trying to reduce your consumption at all costs

2. Not taking into account the field temperature of your

application

3.Overlooking the application's minimal cut-off voltage

4. Choosing a battery that is bigger than necessary

5. Not considering the specific pulse requirements in the

discharge profile of your application

6. Taking the information indicated on the datasheet at face value

7. Believing that a test at ambient temperature is fully

representative of the overall field behavior of your application

| Li-SOCl2(Energy Type) Specifications | ||||||||||

| Model IEC | Nominal Voltage(V) | Dimensions (mm) | Nominal Capacity (mAh) | Standard Current (mA) | Max Continuous Discharge Current (mA) | Max Pulse Discharge Current (mA) | Cut-off Voltage (V) | Weight Approx (g) | Operating Temperature (°C) | |

| ER10450 | AAA | 3.6 | 10.0×45.0 | 800 | 1.00 | 10 | 20 | 2.00 | 9 | -55~+85 |

| ER14250 | 1/2AA | 3.6 | 14.5×25.0 | 1200 | 0.50 | 50 | 100 | 2.00 | 10 | -55~+85 |

| ER14335 | 2/3AA | 3.6 | 14.5×33.5 | 1650 | 0.70 | 50 | 100 | 2.00 | 13 | -55~+85 |

| ER14505 | AA | 3.6 | 14.5×50.5 | 2400 | 1.00 | 100 | 200 | 2.00 | 19 | -55~+85 |

| ER17335 | 3.6 | 17×33.5 | 2100 | 1.00 | 50 | 200 | 2.00 | 30 | -55~+85 | |

| ER17505 | 3.6 | 17×50.5 | 3400 | 1.00 | 100 | 200 | 2.00 | 32 | -55~+85 | |

| ER18505 | A | 3.6 | 18.5×50.5 | 4000 | 1.00 | 100 | 200 | 2.00 | 32 | -55~+85 |

| ER26500 | C | 3.6 | 26.2×50.5 | 8500 | 2.00 | 200 | 400 | 2.00 | 55 | -55~+85 |

| ER34615 | D | 3.6 | 34.2×61.5 | 19000 | 3.00 | 200 | 400 | 2.00 | 107 | -55~+85 |

| ER9V | 9V | 10.8 | 48.8×17.8×7.5 | 1200 | 1.00 | 50 | 100 | 2.00 | 16 | -55~+85 |

| ER261020 | 3.6 | 26.5×105 | 16000 | 3.00 | 200 | 400 | 2.00 | 100 | -55~+85 | |

| ER341245 | 3.6 | 34×124.5 | 35000 | 5.00 | 400 | 500 | 2.00 | 195 | -55~+85 | |